General Atomics Onshores Critical Silicon Carbide Technology to Help Power America's Nuclear Future

SAN DIEGO, CALIFORNIA / ACCESS Newswire / December 18, 2025 / General Atomics Electromagnetic Systems (GA-EMS) is developing scalable, energy-efficient domestic manufacturing processes for silicon carbide (SiC) ceramic matrix composites, offering a U.S.-made solution for a material identified by the Department of Energy (DOE) as critical to advanced energy applications.

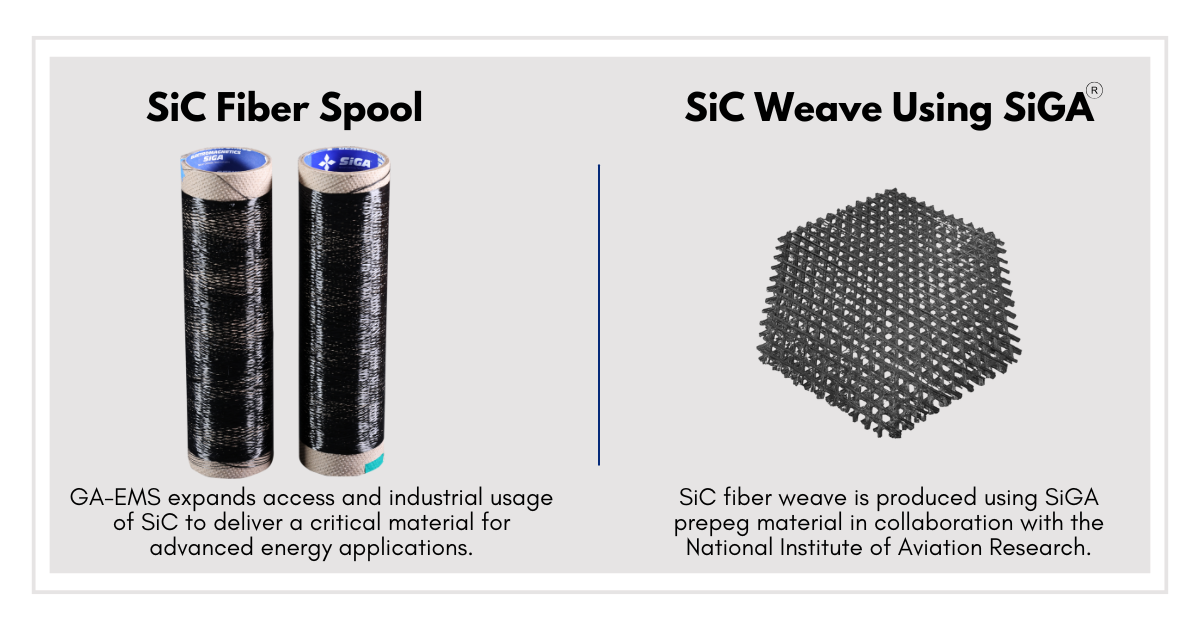

GA-EMS fabrication processes deliver high-quality SiC fiber and ceramic matrix composites through a faster, more affordable process. SiC is a strong, light, and heat-resistant material with major potential for nuclear, turbine and aerospace systems. However, its use has been limited by high material costs and reliance on foreign sources. GA-EMS is expanding access to this important material for demanding energy and aerospace applications by building a domestic supply chain and streamlining production.

"Silicon carbide unlocks enormous potential for the future of nuclear energy, turbine systems, and aerospace platforms," said Scott Forney, president of GA-EMS. "Its strength-to-weight ratio, thermal stability, and resistance to extreme environments make it ideal for advanced propulsion, hypersonics, and space systems. By onshoring SiC fiber production and improving scalability and cost-effectiveness, we're making this essential material more accessible for critical energy applications today, while opening pathways for future aerospace innovation."

GA-EMS is executing two programs funded by the Advanced Materials and Manufacturing Technologies Office (AMMTO) of the DOE. Recent demonstrations include a SiC fiber process that is compatible with continuous production, which can reduce the production cost of domestic SiC fiber by 60%, as well as the utilization of automated fiber placement (AFP) to form complex SiC ceramic matrix composite structures. Together with a hybrid densification process, the team fabricated dense, high-purity SiC/SiC composites 70% faster and with 80% less energy than traditional chemical vapor infiltration.

GA-EMS's work demonstrates a practical path toward U.S.-based manufacturing of silicon carbide materials. By reducing production costs and energy use, the company is helping enable broader deployment of advanced energy systems while contributing to long-term supply chain reliability.

Acknowledgment

This material is based upon work supported by the U.S. Department of Energy's Office of Energy Efficiency and Renewable Energy (EERE) under the Advanced Materials and Manufacturing Technologies Office (AMMTO), Award Number DE-EE0010209.

Legal Disclaimer

The views expressed herein do not necessarily represent the views of the US Department of Energy or the U.S. Government.

About General Atomics Electromagnetic Systems

General Atomics Electromagnetic Systems (GA-EMS) develops innovative technologies to create breakthrough solutions supporting operational environments from undersea to space. From electromagnetic, power generation and energy storage systems and space systems and satellites, to hypersonic, missile defense, and laser weapon systems, GA-EMS offers an expanding portfolio of capabilities for defense, government, and national security customers. GA-EMS also provides commercial products and services targeting hazardous waste remediation, oil and gas, and nuclear energy industries. For more information, visit ga.com/ems.

Media Contact: [email protected]

SOURCE: General Atomics Electromagnetic Systems

Information contained on this page is provided by an independent third-party content provider. XPRMedia and this Site make no warranties or representations in connection therewith. If you are affiliated with this page and would like it removed please contact [email protected]